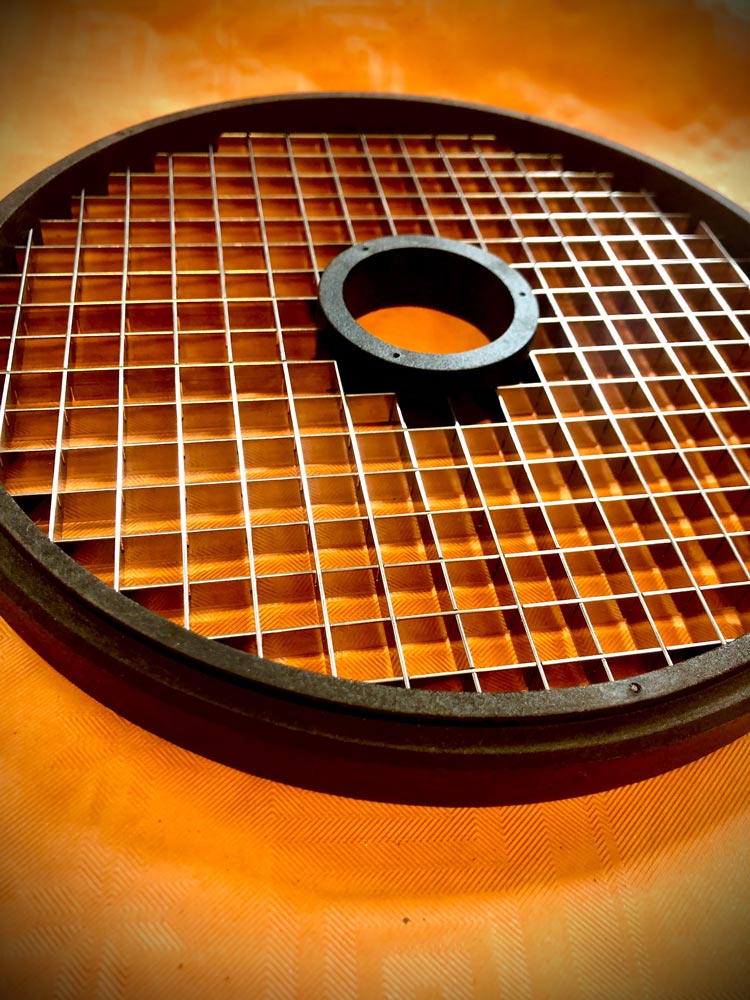

TURRA AND BEMAR: CO-MOLDING OF BLADES FOR MIXERS AND FOOD GRILLS

Bemar is a company founded in 1996 and is the result of the know-how lavished in six centuries of history of blacksmithing in the city of Maniago, a long journey of the Beltrame family with an ancient tradition in the field of cutlery behind it. Now in its fourth generation, Bemar is present specifically in the food industry market producing high-performance blades according to essential quality standards and using CNC machinery, laser cutting machines, and injection presses. The company’s goal is to meet customer expectations through the implementation of cutting-edge production processes dedicated to the manufacturing of stainless-steel blades, sharp belts, and grids, also thanks to the injection molding process with vertical presses.

For this reason, Mr. Marcello Beltrame, owner of Bemar, has chosen Turra as his partner for the production of mixer blades and food grills that offer the possibility of creating strips, slices, and cubes.

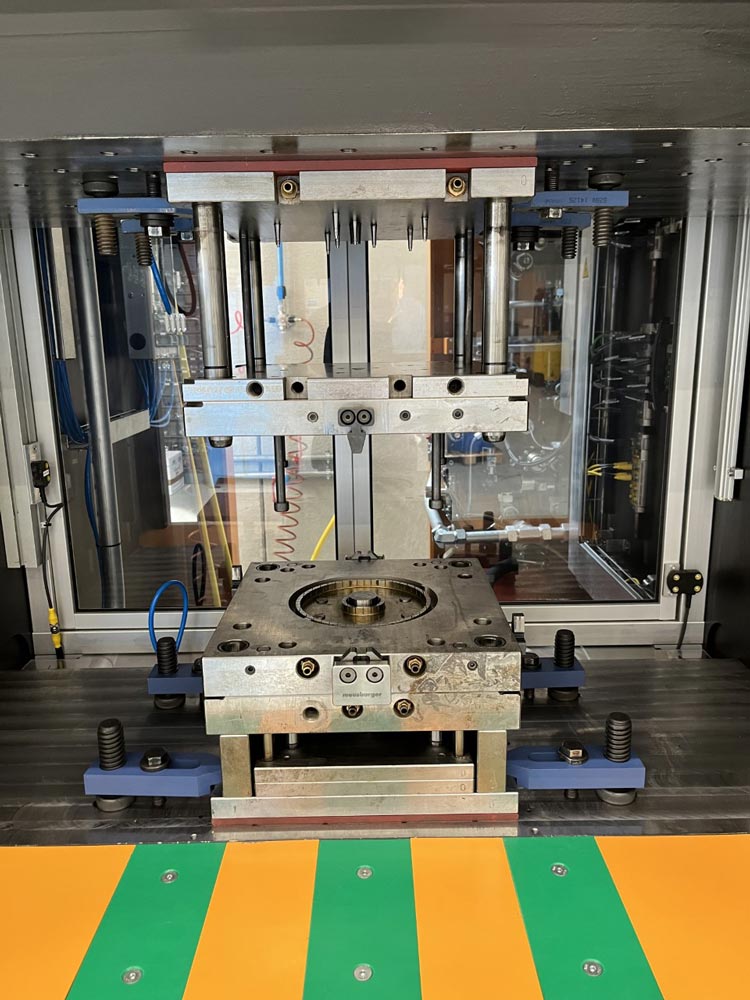

Before contacting Turra, Bemar used a horizontal press to co-mold these types of pieces, not an ideal solution due to the difficulty of loading the inserts inside the press. The requirement was the ability to use the same large molds of the horizontal press on a vertical press. To achieve this a considerable working stroke, a large load base of the molds, and an ergonomic support surface are needed to facilitate human-machine interaction.

Given the low-level production requirement, to meet Bemar’s requests, TURRA proposed an ERGON NT-80 equipped with a fixed mold. This solution — thanks to ergonomic access to the loading area (height 850 mm), the absence of traditional columns replaced by guides and slides on ball bearings and a stroke of 450 mm — has fully satisfied Bemar’s requests allowing them to create pieces of any shape and complexity using big molds.

The ERGON line is also available in a configuration with sliding tables (ERGON ST) or rotary tables (ERGON RT) with a clamping force from 30 to 200 tons.